The SIMATIC S7-200 manual provides comprehensive guidance for understanding‚ programming‚ and troubleshooting the S7-200 PLC‚ covering safety‚ hardware‚ and software tools for efficient automation solutions.

1.1 Overview of the SIMATIC S7-200 PLC

The SIMATIC S7-200 is a compact and flexible programmable logic controller (PLC) designed for industrial automation. It features a modular architecture with central processing units‚ memory modules‚ and communication interfaces. The PLC is ideal for small to medium-sized applications‚ offering reliable performance and easy integration into industrial networks. Its design ensures scalability and adaptability to various control tasks‚ making it a versatile solution for modern automation systems.

1.2 Importance of the Manual for Users

The SIMATIC S7-200 manual is essential for users‚ offering detailed instructions for installation‚ programming‚ and troubleshooting. It ensures safe operation and optimal utilization of the PLC‚ covering technical specifications‚ hardware components‚ and software tools. The manual serves as a critical reference‚ helping users navigate the system’s architecture and resolve common issues effectively‚ thus enhancing productivity and system reliability in automation environments.

Safety Guidelines and Precautions

Adhering to safety guidelines ensures protection for both users and equipment. Proper installation‚ handling‚ and operation are crucial to prevent risks and maintain system integrity effectively.

2.1 General Safety Instructions

Adhering to general safety guidelines is essential for safe operation. Proper installation‚ handling‚ and use of the S7-200 PLC are critical. Always disconnect power before servicing and avoid overloading circuits. Ensure all connections are secure and comply with rated specifications. Use appropriate tools and follow safety standards to prevent hazards. Proper grounding and environmental considerations must be observed. Personal protective equipment should be used when working with electrical systems to minimize risks and ensure safe maintenance procedures.

2.2 Protecting the Product and Connected Devices

Protecting the S7-200 and connected devices involves adhering to environmental and electrical guidelines. Ensure stable power supply to prevent damage from voltage fluctuations. Avoid exposure to extreme temperatures‚ humidity‚ and dust. Use surge protectors and grounding systems to safeguard against electrical surges. Regular maintenance and inspection of connections and components are crucial to prevent wear and tear. Always use approved Siemens accessories to maintain compatibility and longevity of the system‚ ensuring optimal performance and reliability in industrial environments.

System Architecture and Components

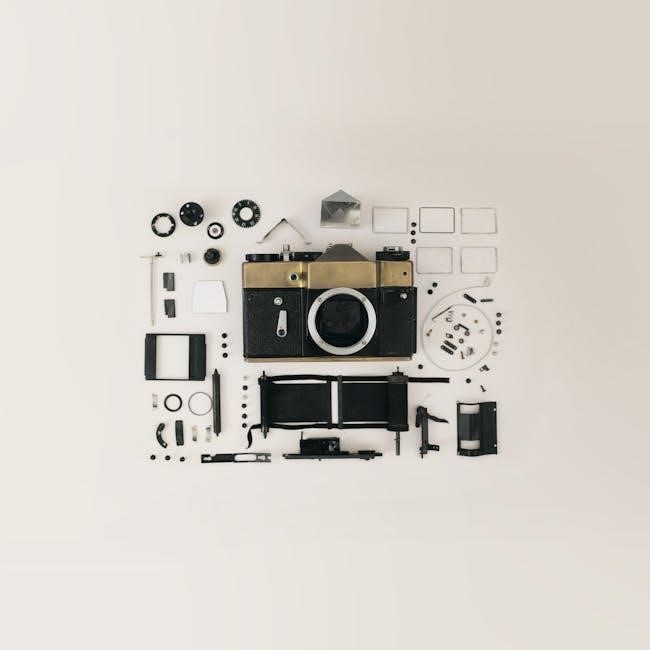

The SIMATIC S7-200 system architecture comprises key components‚ including hardware modules‚ CPUs‚ memory units‚ and expansion options‚ designed for modular and scalable industrial automation solutions.

3.1 Hardware Components of the S7-200

The S7-200 PLC consists of essential hardware components‚ including the CPU module‚ power supply units‚ input/output modules‚ memory modules‚ and communication interfaces. These components work together to enable seamless automation‚ ensuring efficient control of industrial processes. Proper installation and configuration of these modules are crucial for optimal performance and reliability in various applications.

3.2 Central Processing Units (CPUs)

The S7-200 CPUs serve as the brain of the PLC‚ executing control programs and managing data processing. Available in various models like the CPU 224‚ 226‚ and 228‚ these units offer different performance levels; They support memory expansion‚ communication protocols‚ and real-time data processing‚ ensuring flexibility and scalability for diverse automation tasks. Proper CPU selection is key to optimizing system functionality and meeting application requirements.

3;3 Memory Modules and Expansion Options

The S7-200 offers expandable memory modules to enhance data storage and program capacity. These modules‚ including RAM and EEPROM‚ allow users to store larger programs and data logs. Expansion options also support additional I/O modules‚ communication interfaces‚ and specialized function modules‚ ensuring the system can adapt to growing automation demands and complex control requirements efficiently.

CPU Modules and Their Functions

CPU modules serve as the brain of the S7-200 system‚ executing programs‚ managing I/O operations‚ and handling communication. Various CPU types are available to suit different application needs‚ ensuring optimal performance and flexibility in industrial automation tasks while integrating seamlessly with the system architecture for enhanced functionality and scalability.

4.1 CPU 22x with DC Power Supply

The CPU 22x with DC power supply is a reliable processor designed for industrial automation‚ offering efficient control and communication. It operates on a 24 V DC power supply‚ ensuring stable performance in various applications. This module features advanced processing capabilities‚ supports multiple I/O configurations‚ and integrates seamlessly with the S7-200 PLC network. Its robust design makes it suitable for applications requiring precise control and durability‚ contributing to scalable and efficient automation solutions.

4.2 Technical Specifications of CPU Modules

The CPU modules for the SIMATIC S7-200 are designed for high performance and reliability in industrial automation. They feature advanced processing capabilities‚ scalable memory options‚ and robust communication interfaces. Technical specifications include support for various I/O configurations‚ high-speed processing‚ and compatibility with the STEP 7-Micro/WIN programming software. These modules are engineered to meet diverse automation needs‚ ensuring efficient and reliable operation in demanding environments.

Programming and Software Tools

The SIMATIC S7-200 manual provides detailed insights into programming tools like STEP 7-Micro/WIN‚ enabling users to create‚ edit‚ and manage PLC programs efficiently for industrial automation tasks.

5.1 STEP 7-Micro/WIN Programming Software

STEP 7-Micro/WIN is a user-friendly programming software for the S7-200 PLC‚ enabling efficient creation‚ editing‚ and monitoring of control programs. It supports ladder logic‚ function block‚ and instruction list programming‚ offering intuitive tools for debugging and testing. The software also provides real-time monitoring of I/O states‚ making it essential for commissioning and troubleshooting automation tasks. Its compatibility with Windows operating systems ensures seamless integration into industrial computing environments.

5.2 Input/Output Addressing Schemes

The SIMATIC S7-200 supports various I/O addressing schemes‚ including direct and symbolic addressing‚ allowing seamless communication between the CPU and external devices. Direct addressing uses physical addresses‚ while symbolic addressing employs logical names for easier programming. These schemes enhance flexibility and simplify configuration‚ ensuring efficient interaction between the PLC and connected peripherals for reliable automation processes and consistent system performance.

Communication Interfaces and Networks

The SIMATIC S7-200 supports various communication interfaces‚ including RS-232 and RS-485‚ enabling integration into industrial networks like PROFIBUS and PROFINET for seamless device interaction and scalable automation solutions.

6.1 Communication Ports and Protocols

The SIMATIC S7-200 offers various communication ports‚ including RS-232 and RS-485‚ with support for protocols like PROFIBUS‚ PROFINET‚ and MODBUS. These interfaces enable data exchange‚ device integration‚ and network connectivity‚ ensuring efficient communication within industrial automation systems. The manual details configuration steps‚ wiring diagrams‚ and troubleshooting tips for these ports and protocols‚ facilitating seamless integration and reliable operation.

6.2 Integration into Industrial Networks

The SIMATIC S7-200 can seamlessly integrate into industrial networks using protocols like PROFIBUS‚ PROFINET‚ and MODBUS. It supports Master/Slave configurations and communicates with other devices efficiently. The manual provides detailed guidelines for setting up network connections‚ ensuring compatibility and reliable data exchange within industrial automation systems. Wiring diagrams and troubleshooting tips are also included to facilitate smooth integration and maintain optimal network performance.

Technical Specifications and Wiring Diagrams

This section provides detailed technical specifications‚ voltage ratings‚ memory capacities‚ and I/O configurations. Wiring diagrams guide proper connections‚ ensuring safe and efficient installations and expansions of the S7-200 system.

7.1 Detailed Technical Data and Ratings

This section outlines the S7-200 PLC’s technical specifications‚ including voltage ratings‚ memory capacities‚ and CPU performance metrics. It details power supply requirements‚ I/O module compatibility‚ and environmental operating conditions‚ ensuring safe and reliable operation across industrial applications. Technical data for CPU modules‚ such as processing speeds and memory configurations‚ are also provided to help users optimize their system setup and performance.

7.2 Wiring Diagrams for Inputs and Outputs

This section provides detailed wiring diagrams for connecting inputs and outputs to the S7-200 PLC. Clear illustrations guide users through proper cable connections‚ ensuring compatibility with digital and analog I/O modules. Color-coded wiring diagrams simplify installation‚ while notes on pin layouts and voltage requirements help prevent errors. Troubleshooting tips address common wiring issues like short circuits or incorrect connections‚ ensuring reliable system operation.

Troubleshooting and Diagnostic Tools

This section covers diagnostic tools and troubleshooting methods for the S7-200 PLC‚ including LED indicators and common issues to ensure efficient problem-solving and system maintenance.

8.1 Diagnostic LEDs and Their Indications

The SIMATIC S7-200 manual details diagnostic LEDs that provide visual status indications. The green LED indicates normal operation‚ while the red LED signals faults. Specific LEDs like RUN and ERR show system status and errors. These LEDs are crucial for quick troubleshooting and maintenance‚ ensuring efficient problem-solving and system reliability.

8.2 Common Issues and Solutions

Common issues with the S7-200 include power supply faults‚ communication errors‚ and I/O module malfunctions. Solutions involve checking power connections‚ verifying communication settings‚ and ensuring proper wiring. The manual provides detailed troubleshooting steps‚ such as resetting modules or updating firmware. Regular maintenance and software updates can prevent many issues‚ ensuring reliable operation and minimizing downtime in industrial automation systems.

Additional Resources and Training

The S7-200 Quick Reference Guide provides a concise overview‚ while comprehensive training programs at Siemens centers offer practical and theoretical knowledge to master PLC operations effectively.

9.1 S7-200 Quick Reference Guide

The S7-200 Quick Reference Guide offers a concise yet comprehensive overview of essential PLC functions‚ including wiring diagrams‚ programming software‚ and I/O addressing. Designed for quick access‚ it simplifies troubleshooting and operation. This guide is ideal for both experienced users and newcomers‚ providing clear‚ straightforward information to enhance productivity and efficiency in automation tasks.

9.2 Training Opportunities at Siemens Centers

Siemens Training Centers offer comprehensive courses on the SIMATIC S7-200‚ providing hands-on experience and expert instruction. These programs cover PLC programming‚ hardware configuration‚ and troubleshooting‚ ensuring participants gain practical skills. Designed for both beginners and advanced learners‚ the curriculum focuses on real-world applications‚ enabling professionals to master automation tasks efficiently and effectively.

The SIMATIC S7-200 manual serves as a vital resource for mastering the PLC system‚ offering detailed insights into its functionality‚ programming‚ and maintenance. It caters to both beginners and experienced users‚ ensuring efficient automation solutions. By following the guidelines and utilizing the provided tools‚ users can optimize their workflows‚ enhance productivity‚ and troubleshoot effectively‚ making it an indispensable guide for industrial automation tasks.

Leave a Reply