This manual provides comprehensive insights into the installation, operation, and maintenance of Watts Pressure Reducing Valves, ensuring optimal performance and compliance with local building codes and standards.

Overview of the Watts Pressure Reducing Valve

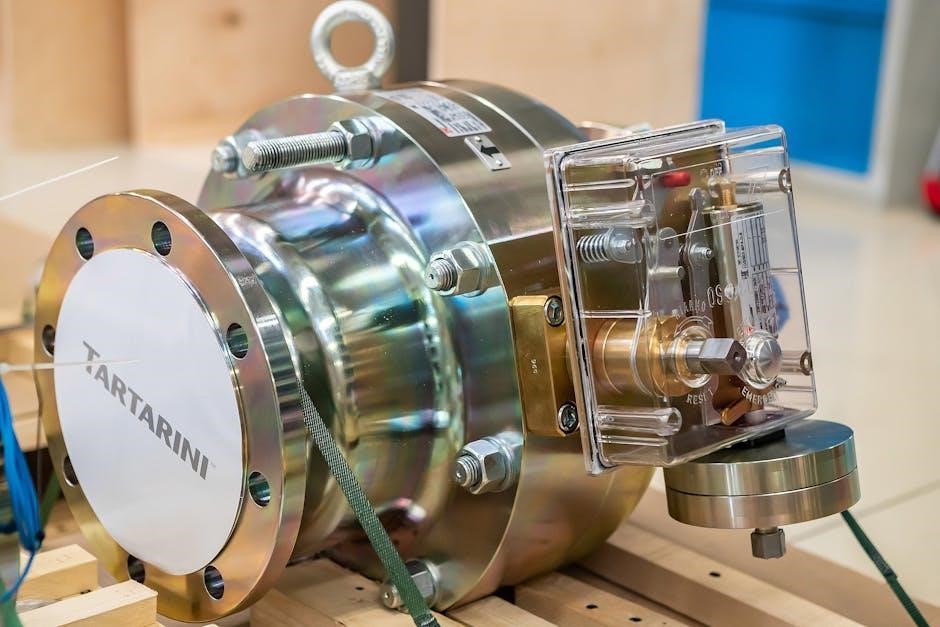

The Watts Pressure Reducing Valve is a sophisticated device designed to regulate and stabilize water pressure in residential and commercial plumbing systems. Its primary function is to reduce high inlet pressure to a safe, consistent outlet pressure, protecting appliances and fixtures from damage. Available in various models, including adjustable options, this valve ensures precise control over water flow. With features like thermal expansion bypass and low-flow capabilities, it offers versatility for different applications. Installation must comply with local codes and standards, such as AS/NZS 3500, to ensure safety and optimal performance.

Importance of Using a Pressure Reducing Valve

A pressure reducing valve is essential for safeguarding plumbing systems from excessive water pressure, which can damage pipes, fixtures, and appliances. By regulating water flow to a consistent, safe level, it prevents leaks, bursts, and premature wear. This valve also helps conserve water by reducing waste from over-pressure and minimizes noise in plumbing systems. Additionally, it ensures appliances operate efficiently, protecting them from potential damage caused by high-pressure surges. Installing a pressure reducing valve is a critical step in maintaining a reliable and long-lasting water supply system.

Key Features of the Watts Pressure Reducing Valve

The Watts Pressure Reducing Valve is renowned for its durability and precise pressure regulation. It features an adjustable design, allowing users to set desired outlet pressure easily. Equipped with a spring and diaphragm mechanism, it ensures consistent performance. The valve is compatible with various pipe sizes and types, making it versatile for different plumbing systems. Additionally, it includes a built-in strainer to protect against debris. Compliance with AS/NZS 3500 standards and factory preset settings enhance its reliability. These features make it a trusted solution for residential and commercial water pressure management.

Technical Specifications and Requirements

Watts Pressure Reducing Valves are designed for compatibility with various pipe sizes and types, ensuring reliability and adaptability across different plumbing systems and pressure conditions.

Pressure Rating and Adjustment Range

The Watts Pressure Reducing Valve is designed to handle a wide range of pressure settings, typically preset at 50psi but adjustable to meet specific system requirements. The adjustment range allows for precise control, ensuring optimal performance across various applications. Users can adjust the reduced pressure by loosening the adjusting screw nut and turning the screw clockwise to increase or counterclockwise to decrease the setpoint. This feature ensures compatibility with different plumbing systems and compliance with local building codes and standards like AS/NZS 3500.

Compatible Pipe Sizes and Types

The Watts Pressure Reducing Valve is compatible with a variety of pipe sizes and types, ensuring versatility in different plumbing systems. It can be installed on cold water supply lines and is suitable for use with copper, PEX, and PVC pipes. The valve is designed to fit standard pipe sizes, typically ranging from ½” to 2″, depending on the specific model. Compatibility with various pipe materials ensures reliable performance and ease of installation, while adhering to local codes and standards. Proper selection of pipe size and type is essential for optimal valve performance and system efficiency.

Compliance with Local Codes and Standards

The Watts Pressure Reducing Valve is designed to comply with local plumbing codes and standards, including AS/NZS 3500 and other relevant building regulations. Compliance ensures safe and regulated installation, operation, and maintenance of the valve. Adherence to these standards guarantees that the valve meets safety, performance, and environmental requirements.Licensed plumbers must install the valve in accordance with local codes to ensure compliance and avoid potential legal or safety issues. Proper compliance also ensures the valve operates efficiently and reliably within the plumbing system. Always verify local regulations before installation.

Installation Instructions

Installation requires a licensed plumber following local codes like AS/NZS 3500. Ensure proper setup for safe, efficient operation and optimal performance of the Watts Pressure Reducing Valve.

Pre-Installation Checklist

Before installation, ensure the following: hire a licensed plumber, comply with AS/NZS 3500 and local codes, shut off the main water supply, drain the system, and verify pipe compatibility. Check the valve location, ensuring it’s accessible and protected. Install a strainer upstream to prevent debris. Confirm the factory preset pressure matches requirements. Familiarize yourself with local regulations and safety standards. Ensure all tools and materials are ready, including adjusting screws and lock nuts. Follow the manufacturer’s guidelines for proper setup and safe operation of the Watts Pressure Reducing Valve.

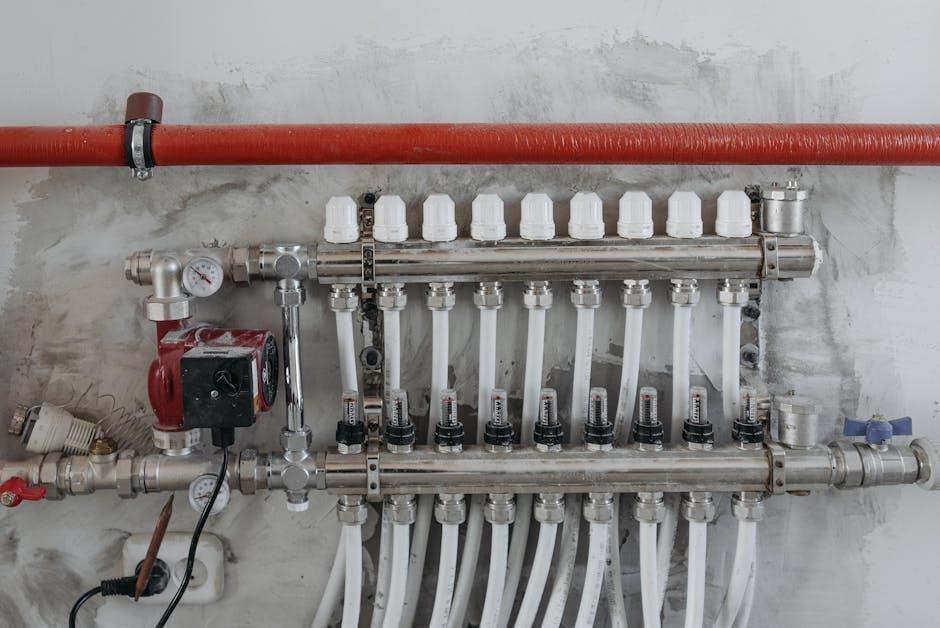

Step-by-Step Installation Process

Shut off the main water supply and drain the system. 2. Install a strainer upstream of the valve to prevent debris. 3. Mount the valve in a vertical or horizontal position, ensuring accessibility; 4. Secure the valve to the pipe using appropriate connectors. 5. Attach the adjusting screw and lock nut, ensuring the factory preset pressure is set correctly. 6. Gradually turn on the water supply and check for leaks. 7. Test the outlet pressure and adjust as needed using the adjusting screw. 8. Tighten the lock nut after adjustments and ensure proper operation.

Post-Installation Testing and Verification

After installation, turn the water supply on gradually to avoid pressure surges. Check all connections for leaks. Measure the outlet pressure using a gauge to ensure it matches the desired setpoint. Test the valve under various flow conditions to verify consistent pressure reduction. Ensure the adjusting screw operates smoothly when fine-tuning the pressure. Verify that the valve maintains the set pressure with both high and low flow rates. Record the initial settings for future reference and perform a final system flush to remove any debris.

Operating Principle of the Watts PRV

The Watts PRV operates by balancing outlet pressure and spring compression, automatically reducing inlet pressure to a constant outlet pressure setpoint, ensuring stable water flow.

How the Pressure Reducing Valve Works

The Watts Pressure Reducing Valve reduces high inlet pressure to a constant, lower outlet pressure. It operates using a spring and diaphragm mechanism. When inlet pressure increases, the diaphragm moves downward, closing the valve to reduce flow. As outlet pressure drops, the spring pushes the diaphragm up, opening the valve to restore flow. This continuous balancing act ensures stable outlet pressure, regardless of fluctuations in inlet pressure, providing consistent water flow to appliances and systems.

Role of the Spring and Diaphragm

The spring in the Watts Pressure Reducing Valve sets the desired outlet pressure by compressing to resist diaphragm movement. The diaphragm responds to changes in outlet pressure, moving upward or downward to open or close the valve. When inlet pressure increases, the diaphragm moves down, closing the valve to reduce flow. Conversely, when outlet pressure drops, the spring pushes the diaphragm up, opening the valve to allow more flow. This balanced interaction ensures consistent pressure regulation, maintaining the preset outlet pressure regardless of inlet fluctuations.

Balancing Outlet Pressure and Spring Compression

Balancing outlet pressure and spring compression is crucial for optimal valve performance. The spring compression is adjusted to match the desired outlet pressure setpoint. When outlet pressure increases beyond this setpoint, the spring compresses further, closing the valve to restrict flow. Conversely, if outlet pressure drops below the setpoint, the spring decompresses, opening the valve to increase flow. This precise balance ensures stable pressure regulation, preventing over-pressurization and maintaining system safety while meeting specific application requirements for water pressure management.

Adjustment and Calibration

Adjustment and calibration involve setting the desired outlet pressure by loosening the adjusting screw nut and turning the screw clockwise to increase or counterclockwise to decrease pressure.

Factory Preset Pressure Setting

The Watts Pressure Reducing Valve is factory preset to a default pressure setting of 50psi to ensure safe and efficient operation. This preset configuration provides a reliable starting point for most residential and light commercial applications. However, the valve allows for field adjustments to accommodate specific system requirements. The adjustment process involves loosening the lock nut and turning the adjusting bolt clockwise to increase or counterclockwise to decrease the outlet pressure. This feature ensures flexibility and adaptability to varying water pressure conditions while maintaining optimal performance.

Procedure for Adjusting Reduced Pressure

To adjust the reduced pressure, first loosen the adjusting screw nut by turning it counterclockwise. Next, turn the adjusting screw clockwise to increase the outlet pressure or counterclockwise to decrease it. After making the desired adjustment, tighten the adjusting screw nut securely. It is essential to test the system after adjustments to ensure the pressure meets the required specifications. Proper adjustment ensures optimal performance and prevents damage to downstream fixtures and appliances. Always refer to the manufacturer’s guidelines for specific instructions tailored to your valve model.

Tightening and Loosening the Adjusting Screw

Loosening the adjusting screw nut allows for pressure modifications. Turn the nut counterclockwise to release tension on the screw; After adjusting the screw, tighten the nut clockwise to secure the setting. Proper tightening ensures stability in outlet pressure. Always follow manufacturer guidelines to avoid over-tightening, which could damage the valve. Use an appropriate wrench for these adjustments to maintain precision and prevent potential leaks or malfunctions. Regular inspection of the screw and nut ensures continued optimal performance and longevity of the pressure reducing valve.

Maintenance and Troubleshooting

Regularly inspect the valve for wear and tear. Clean or replace parts as needed. Check for leaks and ensure proper pressure settings. Schedule annual professional checks.

Regular Maintenance Requirements

Regular maintenance is essential for optimal performance. Inspect the valve for wear, corrosion, or leaks. Clean or replace screens and diaphragms as needed. Check pressure settings annually to ensure they remain within the specified range. Lubricate moving parts if recommended. Replace the main valve seat and disc every 5-7 years or as needed. Keep a maintenance log to track inspections and repairs. Always follow the manufacturer’s schedule for professional servicing to ensure compliance and longevity of the valve.

Common Issues and Solutions

Common issues include leaks, incorrect pressure settings, and blockages. For leaks, tighten connections or replace worn gaskets. If pressure is too high or low, adjust the spring tension by turning the adjusting screw. Blockages in the strainer or valve seat should be cleaned or replaced. Regular inspection of the diaphragm and spring ensures proper function. If issues persist, refer to the manual or contact a professional. Always follow manufacturer guidelines for repairs to maintain warranty and ensure safety.

When to Replace the Valve

Replace the valve if it shows significant wear, such as a damaged diaphragm or spring, or if it fails to regulate pressure effectively. If the valve cannot maintain the set pressure or leaks persistently, replacement is necessary. Corrosion, mineral buildup, or physical damage also warrant replacement. Always consult the manual or contact a professional for proper replacement procedures to ensure safety and optimal performance. Regular inspections can help identify when replacement is needed to prevent system failures.

Safety Considerations

Safety Considerations

Ensure all installations are performed by licensed professionals, adhering to AS/NZS 3500 and local codes. Always handle high-pressure situations with caution to prevent accidents.

Installation by a Licensed Plumber

Installation must be conducted by a licensed plumber to ensure compliance with AS/NZS 3500 and local building codes. Proper techniques and manufacturer guidelines are crucial for safe and accurate setup. The valve should be installed on the water service pipe, with models like Series 223 or 223S recommended. Adherence to these standards prevents potential issues such as leaks or incorrect pressure settings. Always follow the manufacturer’s instructions to guarantee optimal performance and safety.

Adherence to AS/NZS 3500 and Local Building Codes

Strict compliance with AS/NZS 3500 and local building codes is essential when installing a Watts Pressure Reducing Valve. These standards ensure the valve operates safely and efficiently, meeting all regulatory requirements. Proper installation by a licensed plumber guarantees adherence to these codes, minimizing risks and ensuring system integrity. Always verify that the valve meets local specifications and that all installations align with current regulations for optimal performance and legal compliance. This adherence is critical for maintaining water quality and system reliability.

Handling High Pressure Situations

High water pressure can cause damage to plumbing systems, making it essential to manage such situations effectively. The Watts Pressure Reducing Valve is designed to reduce fluctuating high-pressure water supply to a safe, constant level. Proper installation by a licensed plumber ensures optimal performance and safety. Always follow local building codes and manufacturer guidelines to handle high pressure situations effectively. Regular maintenance and inspections are crucial to ensure the valve operates reliably, protecting your plumbing system from potential damage caused by excessive pressure.

Additional Components and Accessories

Essential accessories like expansion tanks, relief valves, and thermal expansion bypass models complement the Watts Pressure Reducing Valve, ensuring system stability and optimal performance under varying conditions.

Use of Strainers and Filters

Strainers and filters play a crucial role in protecting the Watts Pressure Reducing Valve from debris and contaminants. They should be installed upstream of the valve to prevent clogging and ensure smooth operation. Regular cleaning of strainers is essential to maintain optimal performance. Filters are particularly recommended in areas with poor water quality to minimize sediment buildup. The Watts Regulator Company Series 223 and 223S models often include strainers to enhance reliability. Proper maintenance of these components ensures the valve functions effectively and prolongs its lifespan.

Thermal Expansion Bypass Models

Watts Thermal Expansion Bypass models are designed to address both high water pressure and thermal expansion in closed water systems. These valves integrate a bypass mechanism to relieve excess pressure caused by water heating, preventing damage to plumbing fixtures. They are particularly useful in systems with check valves or backflow preventers, where thermal expansion cannot naturally escape. By combining pressure reduction with thermal relief, these models offer a comprehensive solution for safe and efficient water system operation, ensuring compliance with local codes and standards like AS/NZS 3500.

Expansion Tanks and Relief Valves

Expansion tanks are essential for managing thermal expansion in closed water systems, working alongside pressure reducing valves to prevent excessive pressure buildup; Watts recommends using models like the DET expansion tank or Governor 80 ballcock for reliable performance. Relief valves, such as the 530C calibrated pressure relief valve, are also critical for safely releasing excess pressure. These components ensure system safety and efficiency, particularly in scenarios where thermal expansion could otherwise cause damage. Proper installation and sizing are vital to maintain optimal functionality and compliance with local codes and standards like AS/NZS 3500.

Downloads and Technical Documentation

Access comprehensive manuals, guides, and certifications for Watts Pressure Reducing Valves on the official website. Visit the Watts Nordic portal to download specific documentation for models like DRVN.

Accessing Manuals and Guides

For detailed instructions and technical specifications, visit the official Watts website or the Watts Nordic portal. Manuals for models like the DRVN are readily available for download. These resources include installation guides, operational manuals, and certification documents. Users can access compliance declarations, technical data sheets, and troubleshooting tips. The portal is organized by product type, making it easy to find specific documentation. Ensure you select the correct model and region for accurate information. These guides are essential for proper installation, maintenance, and troubleshooting of Watts Pressure Reducing Valves.

Training Materials and Resources

Watts offers comprehensive training materials to enhance understanding and skills in installing and maintaining pressure reducing valves. Online courses, instructional videos, and downloadable PDF guides are available through the Watts Nordic website. These resources cover topics such as valve operation, adjustment techniques, and troubleshooting common issues. Additionally, hands-on training sessions are recommended for technicians to gain practical experience. These materials ensure that professionals can install and service Watts valves effectively, adhering to industry standards and best practices for optimal performance and longevity of the equipment.

Certifications and Compliance Documents

Watts Pressure Reducing Valves are certified to meet international standards, including CE marking and compliance with AS/NZS 3500. These certifications ensure the valves meet safety and performance requirements. Compliance documents, such as ISO 9001 quality management certifications, are available for verification. All necessary certifications and compliance documents can be accessed through the Watts Nordic website, ensuring installation meets local building codes and regulations. These documents are essential for verifying the valve’s suitability for specific applications and ensuring compliance with industry standards.

Training and Certification

Professional training is essential for correct installation and maintenance of Watts PRVs. Recommended courses cover installation, maintenance, and troubleshooting, ensuring technicians meet certification requirements and compliance standards.

Importance of Professional Training

Importance of Professional Training

Professional training ensures proper installation, maintenance, and troubleshooting of Watts PRVs, adhering to safety and compliance standards. It equips technicians with in-depth knowledge of valve operations, adjusting procedures, and compliance requirements. Proper training reduces installation errors, enhances system performance, and extends valve longevity. It also ensures adherence to local codes and manufacturer guidelines, minimizing risks and liability. Additionally, trained professionals can efficiently address common issues, perform regular maintenance, and understand when valve replacement is necessary, ensuring optimal functionality and safety in water pressure regulation systems.

Recommended Courses for Installation and Maintenance

Recommended courses for installing and maintaining Watts PRVs include training programs offered by Watts Nordic and HVAC/plumbing technical schools. These courses cover valve operation, adjustment procedures, and compliance with local codes. Participants learn about pressure regulation principles, troubleshooting common issues, and performing routine maintenance. Practical workshops provide hands-on experience with models like the DRVN. Certification programs ensure technicians meet industry standards, while manufacturer-specific training enhances understanding of Watts products. These resources are available through Watts Nordic’s technical documentation and training portals, ensuring professionals are well-equipped to handle PRV systems effectively.

Certification Requirements for Technicians

Technicians installing and maintaining Watts PRVs must meet specific certification requirements, including compliance with local plumbing codes and manufacturer standards. Certification typically involves passing exams and completing training programs approved by industry bodies. Many jurisdictions require technicians to hold a valid plumbing license, ensuring adherence to safety and performance standards. Additionally, manufacturer-specific certifications, such as those offered by Watts, may be necessary for specialized valve models like the Series 223 or 223S. Ongoing education and updates on new technologies are essential to maintain certification and ensure optimal valve performance.

This manual provides essential guidance for installing, maintaining, and operating Watts Pressure Reducing Valves, ensuring optimal performance, safety, and compliance with local plumbing standards and regulations.

The Watts Pressure Reducing Valve manual provides detailed guidance on installation, maintenance, and operation. It emphasizes the importance of proper setup by licensed professionals, adherence to local codes, and regular servicing. Key features include adjustable pressure settings, thermal expansion bypass models, and compatibility with various pipe sizes. The manual also covers troubleshooting common issues and highlights the role of strainers and filters for optimal performance. By following the guidelines, users can ensure safe, efficient, and long-lasting operation of the valve, maintaining stable water pressure in residential and commercial systems.

Final Tips for Optimal Performance

Regularly inspect and maintain the valve to ensure longevity. Always adjust the pressure setting according to the manual’s guidelines. Use compatible strainers and filters to prevent debris buildup. For thermal expansion, consider bypass models. Ensure proper installation by licensed professionals. Refer to the manual for specific instructions and adhere to local codes. Monitor outlet pressure and adjust as needed. Keep spare parts readily available. Schedule periodic checks to avoid sudden failures. By following these tips, you can maximize the valve’s efficiency and reliability over time.

Leave a Reply